What is Roof Sheathing?

When most people think of their roof, they picture shingles or tiles. But there's a critical layer underneath that forms the foundation of your roofing system: the roof sheathing. So, what is roof sheathing, and why does it matter?

In this comprehensive guide from Tony’s Roofcare Inc., we’ll break down what is roof sheathing, the different types, materials, costs, and why it plays a vital role in the structural integrity of your home. Whether you’re replacing your roof or just curious about its components, this blog is packed with the essential information you need to know.

What is roof sheathing is a question that many homeowners ask when they’re considering a roof replacement or dealing with persistent roof leaks. Understanding this element is crucial for long-term performance and protection.

What Is Roof Sheathing?

Roof sheathing is the sturdy wooden layer attached to the structural framework of your roof. It serves as the base for roofing materials such as shingles, underlayment, and flashing. Without this integral component, your roof would lack the structural foundation it needs to perform properly.

Also referred to as roof decking, this component links the roof structure with the weatherproofing layers. It provides a consistent, solid surface for fastening roofing materials, helps resist shifting loads, and contributes to the overall strength of the roof system.

For homeowners in regions with heavy rain or snowfall, what is roof sheathing becomes especially important. It ensures that the load from precipitation is evenly distributed across the entire roof and absorbed safely by the house’s framing.

The Function of Roof Sheathing: Why It’s Critical

Roof sheathing is more than just a wooden platform. It serves several essential roles in a well-constructed roofing system:

- Acts as the anchor layer for roofing components

- Helps distribute loads from snow, rain, and debris

- Improves resistance against wind uplift

- Provides a fire-retardant barrier when treated

- Helps prevent leaks when paired with quality underlayment

- Enhances the structural integrity of the roofing system

If you're wondering what is roof sheathing doing to protect your home, these key functions highlight its critical importance.

Types of Roof Sheathing: Plank vs. Sheet

There are two main forms of roof sheathing: plank and sheet. Each has specific characteristics and is suited for particular applications.

Plank Sheathing

Plank sheathing was the norm before the development of modern panel products. These boards are typically 1x6 or 1x8 in size and laid across the roof structure with small gaps between them.

In older homes, you might still encounter plank sheathing during a roof replacement. Although historically durable, today it often falls short of modern building code standards due to spacing inconsistencies and structural limitations.

Some roofing materials like wood shakes may still be installed over plank sheathing in ventilated assemblies. However, in most cases, it's recommended to overlay or replace plank sheathing with modern panels for strength and compliance.

Sheet Sheathing

Sheet sheathing refers to large, flat wood panels like plywood or OSB that cover the entire roof deck. It's the modern standard due to its affordability, ease of installation, and compatibility with all roofing types.

Sheet sheathing offers uniform load distribution, fewer seams, and a continuous surface for attaching fasteners and sealants. It also complies with current code requirements and manufacturer installation instructions, making it the go-to choice for roof replacements and new construction.

If you’ve ever asked what is roof sheathing and how it’s applied, understanding the difference between plank and sheet types is essential.

Roof Sheathing Materials: What It’s Made From

OSB (Oriented Strand Board)

OSB is composed of compressed wood strands bonded with resin under heat and pressure. It's available in standard 7/16” thickness and is the most commonly used sheathing product today.

Pros:

- Cost-effective and widely available

- Good structural strength

- Easy to handle and install

Cons:

- Absorbs moisture more readily than plywood

- Takes longer to dry out

- Edges can swell and warp if exposed to prolonged moisture

Despite these concerns, OSB remains popular for budget-conscious projects where proper ventilation and underlayment are used to prevent moisture damage.

Plywood

Plywood is manufactured by layering thin sheets of wood with the grain oriented in alternating directions. This cross-layering makes it highly durable and stable under fluctuating temperatures and moisture levels.

Strengths:

- Superior resistance to swelling and warping

- Dries quickly after exposure

- Holds nails more securely over time

Considerations:

- Typically heavier than OSB

- More expensive per sheet

- Preferred in high-end or high-humidity installations

CDX plywood is the grade most often used in roofing. It offers a high strength-to-weight ratio and excellent longevity when installed with proper weatherproofing layers.

Other Materials

Though less common in residential applications, other sheathing materials include:

- Concrete panels: Used in flat or low-slope commercial roofs demanding high load capacity and fire resistance.

- Exterior gypsum board: Lightweight and fire-resistant, primarily used in fire-rated roof assemblies or specific commercial installations.

These options may be ideal for specialty roof applications, but for standard home roofing, OSB and plywood remain the top choice. Anyone curious about what is roof sheathing made from can benefit from understanding all these material options.

Solid vs. Open Sheathing: Installation Methods

The way roof sheathing is installed can vary depending on the roofing materials being used.

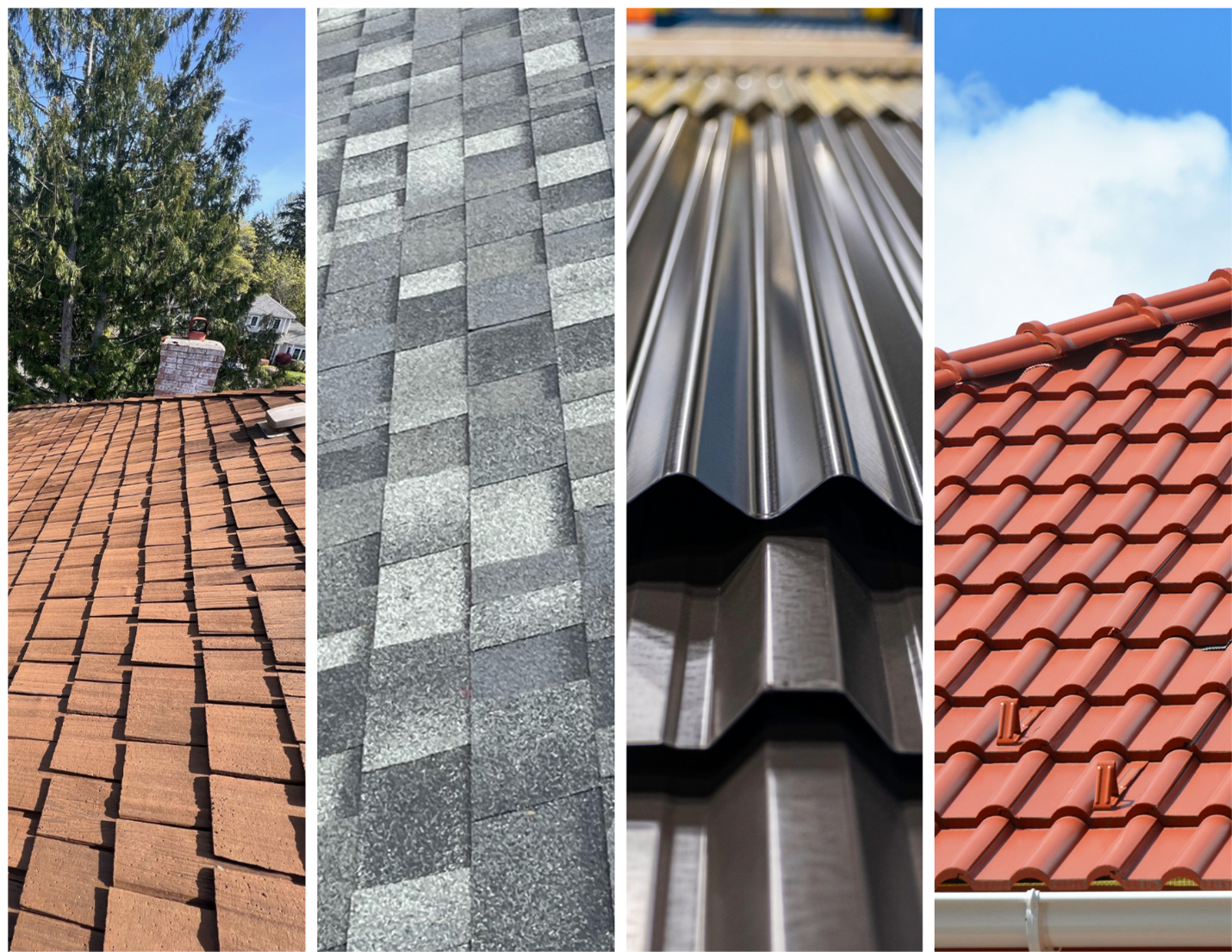

Solid sheathing is a fully covered surface using sheet products or tightly spaced planks. It's required for asphalt shingles, tile, and metal roofing, as these materials need consistent support underneath.

Open sheathing, also called skip sheathing, uses spaced boards with visible gaps. It's used primarily with wood shakes or shingles that benefit from additional airflow beneath.

Each method must follow structural requirements and be tailored to the material it supports. For instance, open sheathing would not pass code in homes requiring asphalt shingles due to the lack of continuous fastening support.

When and Why Roof Sheathing Needs to Be Replaced

Roof sheathing isn't something homeowners often see—but when it fails, the consequences can be serious. Sheathing should be inspected during any roof replacement or when signs of deterioration appear.

Indicators that sheathing needs replacing:

- Soft or spongy roof areas

- Mold, mildew, or rot visible in the attic

- Sagging roof lines

- Persistent roof leaks

- Stains on ceilings or upper walls

If you’re undergoing a roof repair or full roof replacement, your contractor will determine whether a few boards or an entire section of sheathing needs replacement. Modern roofing projects often involve upgrading or replacing sheathing to meet current codes and improve durability.

This is another moment where homeowners might be thinking what is roof sheathing, and realizing its essential role in protecting their investment.

Building Codes That Impact Roof Sheathing

Roof sheathing must meet the 2018 International Residential Code (IRC) and any local variations. One commonly enforced rule involves plank sheathing: gaps between boards must not exceed 1/8”. If they do, the planks must be replaced or overlaid with a continuous sheet deck.

Another key code requirement: roofing must be installed according to manufacturer specifications. This includes fastening methods and surface preparation—both of which are affected by the condition of your sheathing.

Failing to meet these requirements can void product warranties and result in failed inspections. At Tony’s Roofcare Inc., we ensure all sheathing work is code-compliant and structurally sound.

How Roof Sheathing Affects Roof Replacement Costs

Sheathing is one of the more unpredictable cost variables in a roof replacement. Because its condition isn’t fully visible until the tear-off is done, homeowners should be prepared for possible repairs.

Cost considerations include:

- Partial replacement: Replacing individual boards is relatively affordable

- Full redecking: Required if sheathing is extensively rotted or outdated (plank)

- Material differences: Plywood costs more than OSB, both in material and labor

- Additional labor time required for heavier materials

Tony’s Roofcare Inc. includes a line item in our roofing proposals for sheathing replacement. We never charge for what isn’t used and always discuss the condition of your deck before moving forward with new material installation.

Anyone asking what is roof sheathing should also consider how it can influence the budget and scope of a roofing project.

How to Spot Roof Sheathing Issues Before It’s Too Late

While much of your roof sheathing is hidden, there are signs that can alert you to a potential problem:

- Discolored ceilings or attic beams

- Visible mold or musty smells

- Uneven or wavy rooflines

- Roof leaks during rain or snowmelt

- Flaking, spongy, or warped decking visible from the attic

Addressing these signs in time can help avoid major roof replacement or structural damage. Keeping your roof in peak condition means paying attention to every component—including the sheathing.

Understanding what is roof sheathing and its symptoms helps homeowners stay proactive about roof health.

Roof Sheathing in Roof Replacements by Tony’s Roofcare Inc.

At Tony’s Roofcare Inc., roof sheathing assessments are a critical part of every roofing project. Whether we're working on a historic home or a modern structure, we apply decades of experience to ensure every roof has a safe, strong foundation.

Our roof sheathing process includes:

- Thorough evaluation during tear-off

- Removal of all rotted or compromised boards

- Upgrades from outdated plank to sheet materials when needed

- Use of quality OSB or CDX plywood based on structural demand

- Full compliance with IRC and manufacturer standards

Whether your project involves a simple roof repair or a full roof replacement, our team is ready to deliver ideal results using the right combination of roofing materials and structural reinforcement.

Still wondering what is roof sheathing and how we handle it during replacements? We’re here to help every step of the way.

Contact Tony’s Roofcare Inc.

Tony’s Roofcare Inc. is a family-owned roofing company based in Edgewood, WA. We have a proven track record of serving both residential and commercial customers, ensuring high-quality roofing solutions for all. Owner Tony Porco and our team have been serving communities in Pierce and South King counties since 1997, and we stake our reputation on providing homeowners and businesses the highest quality when it comes to roofing materials and customer service. From roof repair to siding services, Tony’s Roofcare Inc. covers a wide range of exterior home improvement needs.

We’re a GAF Master Elite® Certified roofing company, which means that we partner with GAF, North America’s largest roofing manufacturer, for top-quality products and training. GAF’s factory certification program provides assurance to you that your roof will be completed well and professionally. Only 3% of all roofing contractors in the country have qualified as Master Elite! We’re also accredited by the Better Business Bureau and are members of the Roofing Contractors Association.

Tony's Roofcare Inc. is ready to take care of all your exterior home improvement needs. Call us at (253) 893-6848 or submit our online contact request form. We accept cash, check or Visa, Mastercard, Discover or American Express as payment.

Recent Posts